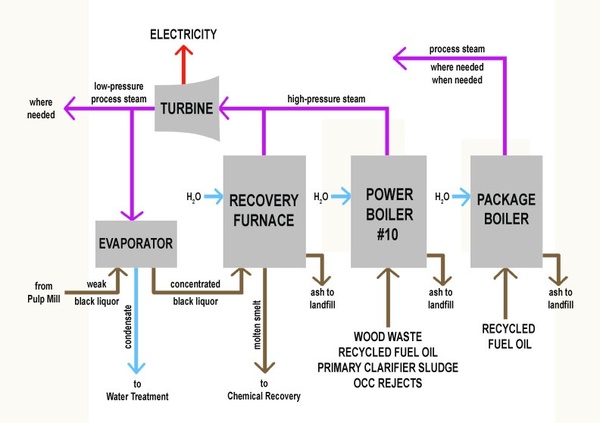

Add a captionThere are three boilers at the mill, each with its own PTWiki page that gets into more detail. The Recovery Furnace and Power Boiler #10 both produce high pressure steam which is fed into an electricity-generating turbine of 13.9 Megawatt capacity. The lower pressure steam leaving this turbine is used as process steam for the various mill operations. The Package Boiler operates intermittently when needed for peak load or maintenance downs.

Add a captionThere are three boilers at the mill, each with its own PTWiki page that gets into more detail. The Recovery Furnace and Power Boiler #10 both produce high pressure steam which is fed into an electricity-generating turbine of 13.9 Megawatt capacity. The lower pressure steam leaving this turbine is used as process steam for the various mill operations. The Package Boiler operates intermittently when needed for peak load or maintenance downs.

Note that the mill is currently (2012) a biomass cogeneration facility. The biomass takes the form of both wood waste input to Power Boiler #10 and the dissolved organics in the black liquor sent to the recovery furnace. The turbine cogenerates electricity from the steam produced on its way to various mill processes, and has done for quite a number of years now.

The proposal currently on the table to build a biomass cogeneration facility would really just expand on what is already in place. The turbine would be replaced with a bigger one (24 Megawatt). Power Boiler #10 would be modified to increase its wood burning capacity and add air pollution control equipment. The Recovery Furnace would be modified to produce steam at a higher pressure and temperature. And a cooling tower would be built to release excess heat into the atmosphere. Less recycled fuel oil (RFO) would be burned because the modified Power Boiler #10 would be using less of it than it does now, and the Package Boiler would, presumably, be used less of the time .